Heart of the matter.

DESIGN

On average we invest 200 hours in the development of each new design that is added to our building portfolio. Most new models shown in our portfolio are designed to be flexible with an ability to customize size, materials, windows, doors, interior configurations, accessories and options. Invariably, each building is different and has an owner’s fingerprints on it.

Our work with each client begins with a conversation and a selection of a building design from our portfolio. During the design phase we work closely with each client to fully understand the scope of each project and what the requirements are. While not necessary, clients are welcome to schedule an appointment to visit our Lambertville, NJ design studio. We’re conveniently situated midway between Philadelphia and New York City. A visit to our studio is not required as the majority of our work is conducted via phone, email, videos/photos, and web conferencing. We provide the same attentive level of hands-on personal service whether a client visits our studio or whether we discuss a project remotely. With each order we provide CAD rendered drawing and construction/assembly documents. 3-D scale model printing is available at an additional charge.

For those considering one of our outbuildings, do give us a call. We look forward to working with you!

MATERIALS

We identify six (6) core components to our buildings. Because our buildings are noticeably different we’d like to explain a few material reasons why that makes a difference:

We like to say our buildings have good “bones.” It’s a signature look unique to our company and the very first thing someone notices and comments on when they step inside our buildings—it feels “solid.” Typical framing uses fir, a softwood with noticeable knots, twists and a nominal measure of 1-1/2” x 3-1/2”. You can find these “sticks” at your local Home Depot or Lowe’s for less than $4.00 each. If you’re lucky you’ll find a few that are straight and true.

We take a fundamentally different approach to framing that is more akin to cabinetmaking. We use poplar, a far superior hardwood (not available in local markets) that we first cut to “rough and green” and then kiln dry (a critical stage) to 10-12% moisture prior to finish milling. We dimension our poplar to a true measure 2” x 4” S4S (square 4 sides). This is more than 50% material when compared to a common fir stud! We mill more than 100,000 board feet of poplar annually that allows us to pass along significant scale savings to our clients.

Our standard frame is an open, “cottage frame”. This imparts a charming, relaxed, yet sophisticated appearance. Think “shabby chic.” For those who prefer a closed wall appearance we offer a variety of options, including bead board, ‘V’ groove, cedar and reclaimed barn wood—any of which retain a cottage look.

The way a frame is engineered makes a fundamental difference in the structural integrity of a building so we take a different approach here too. We ”let-in” diagonal braces into our wall sections for lateral strength and we rabbet in horizontal frame members. We use a double top plate that is half-lapped with the adjoining walls. Excuse the trade lingo. What it means is that we go the extra distance to engineer our structure so that it will stand up to the elements and afford you peace of mind. When complete our buildings are atypically heavy which means they’re not going anywhere!

It’s important to remember that an outbuilding is exposed to weather and critters. With this in mind we design and engineer our building sub-floor to acclimate to moisture, heat, humidity and freeze. Our buildings are constructed on a pressure-treated foundation that consists of runners, floor joists, rigid insulation, vapor barrier, sub-floor, wire mesh and finish floor. All four sides of the 4 x 4 underside foundation are face trimmed with cypress for a fully finished appearance.

Our standard flooring is 5” Tongue and Groove (T & G) cypress. We face nail authentic reproduction rosehead nails to our cypress floorboards to impart character and distinction. In addition, we offer a range of floorboard options, including mahogany, IPE, cork tile, and reclaimed barnwood flooring. Floorboards are unfinished but can be finished to your specification with stain, clear coat, paint, or tung oil.

Our standard siding is a premium, architectural grade cypress with a historically accurate bead profile. We also offer a plain bevel siding. Our siding is installed with a 6” exposure. Why cypress? It’s a wonderful material to mill and has great integrity and longevity. Because cypress does not leech resins or tannins it finishes beautifully. Perhaps the best quality is that cypress is inherently mildew, mold, rot, moisture and insect resistant. These are qualities that more common pine does not offer.

We also offer a range of siding options that include cedar shake, board and batten, vertical ‘V’ groove, and, upon request, Hardiplank. We offer an option for siding to be factory finished with acrylic primer and buffed so that it is fully sealed and protected until ready to finish with final topcoat after installation. Choice of siding is an aesthetic decision.

Like our siding, trim is cypress. We use lock miter joinery on our corner boards so there is no seam movement or separation. Window casing with bead profile is pre-assembled with our window frames.

One of the defining characteristics of our outbuildings is the steep roof pitch we incorporate into the design. This also creates a volume feel on the interior and also provides an option for loft storage. Our standard roofing is #1 Grade Hand-split Western Red Cedar Shakes. Cedar is extremely versatile and adaptable to a variety of styles so it accounts for approximately 80% of our orders. Cedar will patina to either a silver-grey or brown depending on geographic location. If preferred the cedar shakes can be stained post-installation.

In addition to cedar we offer a variety of materials, including Ecoslate, a recycled rubber “slate” that is available in a range of colors. This is a very durable material and qualifies for Leeds® certification. We also offer architectural grade asphalt shingles from any number of manufacturers. We offer two metal roofs, one a standing seam copper; the other a standing seam steel available in a variety of epoxy enamel colors. Use of any alternate roofing material to cedar requires a full sheathing underlayment unlike the lathing with cedar shingles.

Roof options include a selection of roof brackets, braces, and finials.

Our subcomponents are designed and manufactured in-house. That’s important to know because it makes a difference. First, you won’t find our subcomponents elsewhere. Second, we build them right, without compromise. Subcomponents are pre-assembled and may be pre-finished for easy installation. At present we do not sell our windows, doors, and cupolas independent of the building KIT.

We offer a variety of fixed and operative window styles and sizes, any of which can be selected for use in your building. Our awning-style windows (hinged at top) are crafted of select mahogany, cypress and Spanish cedar—materials chosen for durability and longevity. Sashes have profile muntins and traditional true divided glass panes. For purists, we offer reproduction, seedy glass at an additional charge. Window frame includes weather seal and hand-forged and cast hardware. Exterior casing trim has a bead profile with copper drip cap.To compliment our windows we offer a variety of window shutters and window flower boxes.

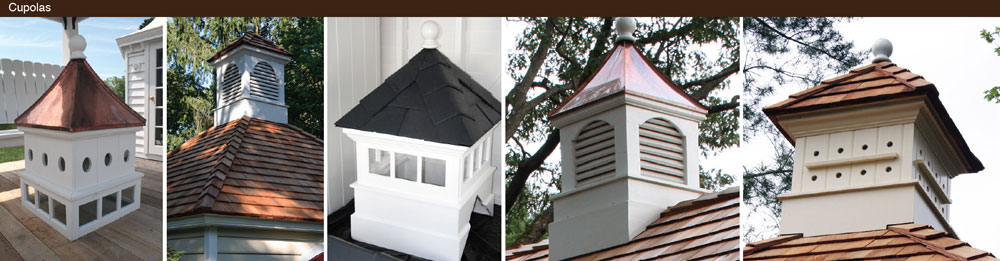

We offer a selection of cupolas to aesthetically and functionally enhance your building. Unlike decorative cupolas that merely sit on a rooftop, ours are vented, screened and open to the building interior to properly draft and circulate air.

We offer a range of exterior and interior options to enhance the utility and aesthetics of your building. Let us know if you have something in mind that is not listed here.

Interior Options

- Storage loft

- Wall Shelving

- Workbench

- Potting Bench w/sink

- Zinc / Soapstone countertops

- Cedar Storage Bench

- Cabinetry

- Partition Walls

- Interior Rooms

- Tool / Towel Racks

- Cubby Boxes

Exterior Options

- Roof Dormers

- Roof Brackets

- Skylights

- Gable Dovecote

- Wall Ventilators

- Window Shutters

- Flower Boxes

- Door Canopies

- Door Ramps

- Door Keepers

- Trellis

- Pergola

- Shower Stall

- Storage Closet

- Lanterns